Aluminium die casting ndi njira yomwe zitsulo zosungunuka za aluminiyamu zimakakamizika kukhala chitsulo kufa kapena nkhungu mopanikizika.Nthawi zambiri amagwiritsidwa ntchito popanga zinthu zambiri ndipo amatha kupanga magawo omwe ali ndi tsatanetsatane wodabwitsa komanso zigawo zolimba kwambiri pamtengo wotsika.Magawo omwe amapangidwa kuchokera ku aluminiyumu akuponyera kufa ali ndi zida zamakina abwino kwambiri ndipo amalimbana ndi dzimbiri, kutentha, komanso kuvala.

• Aluminium die casting imapereka maubwino angapo, ena mwa awa:

• Zida zopepuka komanso zolimba zomwe zimakhala zotsika mtengo kuposa zitsulo zina

• Kuchita bwino chifukwa cha nthawi yochepa yotsogolera komanso kuchepetsa zinyalala

• Kuwonjezeka kwaufulu wapangidwe chifukwa cha kusungunuka kwake, kulola kuti mawonekedwe ovuta apangidwe mofulumira komanso mosavuta

• Kukana kwambiri ku dzimbiri, kutentha, ndi kuvala poyerekeza ndi zitsulo zina

• Kuthekera kwa kupanga misa, ndi ma aloyi ambiri a aluminiyamu amatha kupirira kuthamanga kwambiri ndi kutentha

Aluminium die casting ndi njira yosinthika kwambiri yomwe imagwiritsidwa ntchito popanga magawo osiyanasiyana amakampani osiyanasiyana.Kuchokera pazigawo zamagalimoto kupita ku ma implants azachipatala ndi zina zambiri, kuponya kwa aluminiyamu kumatha kugwiritsidwa ntchito kupanga chilichonse, monga:

• Makampani opanga magalimoto:Magawo osiyanasiyana kuphatikiza ma trim amkati, ma casings otumizira, midadada ya injini ndi ma mounting, ma radiator, ndi makina ochapira.

• Makampani azamlengalenga:Zinthu zovuta monga mapampu, masensa, ma actuators, nsanja za wailesi ndi tinyanga.

• Makampani azachipatala:Zida zapadera kwambiri monga ma valve a mtima oyika, zida zopangira opaleshoni, ma orthotics ndi ma prosthetics.

• Zipangizo zapakhomo:Mahinji ndi zingwe zamafiriji ndi makina ochapira komanso tizigawo ting'onoting'ono timene timafunikira tsatanetsatane watsatanetsatane.

• ndi zina.

Kusankha aloyi yoyenera ya aluminiyamu ya projekiti yanu yoponya kufa ndikofunikira kuti muwonetsetse kuti zomwe mwamaliza zikukwaniritsa zomwe mukufuna.Nawa maupangiri osankha aloyi yoyenera:

• Ganizirani za mphamvu ndi kukhazikika kwa gawo lanu.Ma aloyi osiyanasiyana amapereka mphamvu zosiyanasiyana komanso kukana kuvala, chifukwa chake ndikofunikira kusankha aloyi yomwe ingakwaniritse zosowa zanu.

• Unikani mlingo wofunikira wokana dzimbiri.Ma aluminiyamu aloyi amatha kuthandizidwa ndi kudzoza kuti apereke chitetezo chowonjezera ku dzimbiri, choncho onetsetsani kuti mwaganizira malo omwe mbali zanu zidzafunika kupirira.

• Ganizirani za ndalama zopangira zinthu komanso nthawi yobweretsera.Kutengera ndizovuta za gawolo, ma aloyi osiyanasiyana angafunike njira zosiyanasiyana zopangira kapena kugwiritsa ntchito zida, chifukwa chake ndikofunikira kupenda izi posankha aloyi ya polojekiti yanu.

Zida ndi makina opangira zida zopangira aluminiyamu zimasiyana malinga ndi aloyi yomwe imagwiritsidwa ntchito, kuvutikira kwa gawolo, ndi zina.Nthawi zambiri, ndikofunikira kuganizira zotsatirazi posankha mtundu wa chida:

• Kusankha zida kuyenera kutengera aloyi yomwe imagwiritsidwa ntchito komanso kutentha komwe kumafunikira kuti pakhale zotsatira zabwino.Nthawi zambiri timagwiritsa ntchito H13, SKD61, 8407, 8418, 8433 ndi W360 pazida zakufa.

• Chisamaliro chiyenera kuchitidwa kuti pakhale mbali yokwanira yolembera kuti zigawozo zisunthike mosavuta pakufa pamene zitulutsidwa.Kusanthula kwathunthu kwa DFM kuyenera kuchitidwa musanapange nkhungu.

• Makina achiwiri angafunikire mutatha kuponya kuti mukwaniritse mawonekedwe kapena tsatanetsatane, kumaphatikizapo makina a CNC, kubowola, kugogoda ndi zina zotero.

• Zosankha Zomaliza za Pamwamba monga kuphulitsa mchenga kapena kupukuta kwa vibratory, anodizing, plating kapena penti zingakhalenso zofunika malinga ndi zosowa zanu.

CNC Machining for Die Casted Parts

Kuthetsa mavuto wamba pamapangidwe a aluminiyamu kumatha kukhala njira yowonongera nthawi komanso yokwera mtengo, koma ndikofunikira kuwonetsetsa kuti zigawo zanu zili bwino.Nawa maupangiri othana ndi zovuta zomwe wamba ndi aluminiyamu kufa castings:

• Porosity:Yang'anani gawo lanu pazitsulo zilizonse kapena madera ena omwe angayambitse porosity.Ngati mutapeza, onetsetsani kuti mwawonanso kutentha kwa nkhungu, kuthamanga kwa jekeseni ndi zinthu zina zomwe zingakhudze kudzazidwa kwa chidutswacho.

• Lakwitsidwa:Ngati mupeza kupotoza m'zigawo zina zitachotsedwa pakufa, fufuzani kuti muwone ngati mawonekedwe a nkhungu kapena nthawi zoziziritsa zingayambitse vutoli.Mungafunike kusintha zochunirazi kuti muzitha kupanga mtsogolo kuti muchepetse kusokonekera kulikonse.

• Zowonongeka zapamtunda:Ngati mukukumana ndi vuto lililonse lapamtunda monga ma splay marks kapena zipsepse, onani ngati pali kusagwirizana pakati pa liwiro la jakisoni ndi kusungunuka kwamadzimadzi, chifukwa izi zimatha kuyambitsa izi.Zingakhalenso zofunikira kusintha ma parameters oponya monga kutentha ndi kuzizira kuti muchepetse zolakwika zapamtunda.

Ntchito yatsopano ikayamba, magawo oyeserera mwachangu amafunikira pamitundu yoyesera.Pali njira zambiri zopangira ma prototypes kuphatikiza CNC Machining, Vacuum casting, 3D kusindikiza ndi Rapid prototype tooling.

• Makina a CNC amatha kupanga zitsulo ndi pulasitiki ndi kuchuluka kulikonse.

• Vacuum Casting ndi zigawo za pulasitiki za 5-100 pogwiritsa ntchito nkhungu za silicon

• 3D Printing ndi kusindikiza ABS, PA kapena Zitsulo.Kwa pulasitiki, magawo osindikizidwa a 3D sangathe kupirira kutentha kwakukulu.

• Rapid prototype tooling ndi nkhungu yofewa yopangidwa ndi zitsulo zofewa monga S50C kapena Aluminium.Njirayi imatha kutulutsa magawo ambiri kuposa Vacuum casting.Nthawi yotsogolera ndi yayifupi kuposa zida zopangira ndipo mtengo ndi wotsikanso.

Zida zomwe tagwiritsa ntchito: Pulasitiki ngati PC, PMMA, POM, PP etc,.Zitsulo monga chitsulo, aluminiyamu, mkuwa, mkuwa ndi zina zotero.

Momwe mungapangire mbali za silicon

Kuti mupange gawo la silicone, muyenera kugwiritsa ntchito njira yopangira jekeseni.Izi zimaphatikizapo kusungunula pulasitiki m'makina ojambulira ndikuwabaya m'bowo lotsekedwa, momwe amazizira ndikuuma kuti atenge mawonekedwe omwe akufuna.

Njira zina zomwe mungagwiritse ntchito ndi monga makina osindikizira, vacuum casting, kapena kusindikiza kwa 3D.Njira iliyonse imapereka ubwino ndi zovuta zapadera malinga ndi mtundu wa gawo lomwe mukuyesera kupanga.

Ndi njira zonse, kupeza kutentha koyenera ndi kupanikizika ndikofunikira kuti mukwaniritse miyeso yolondola ndi zinthu zofunika.

Zipangizo zamagawo a silicon

Pali mafakitale ambiri omwe angagwiritse ntchito zida zofewa za silicon monga Magalimoto, Zamankhwala, Zamagetsi, zapanyumba, zakhitchini, ndi zina zambiri.Pazigawo, nthawi zambiri mumatha kupeza izi monga Ma Gaskets, Zisindikizo, O-rings, Zosefera za Air, Hoses, Zida zowunikira, ma foni am'manja, zophimba za kiyibodi, Mawaya ndi kutsekereza zingwe ndi zida zambiri Zachipatala.

Zigawo zopondera zitsulo ndi zigawo zachitsulo zomwe zimapangidwa kudzera muzitsulo zachitsulo, njira yopangira yomwe imaphatikizapo kukhomerera, kudula, kapena kupanga mapepala azitsulo muzinthu zomwe akufuna.

Metal stamping imagwiritsidwa ntchito popanga magawo amakampani osiyanasiyana kuphatikiza mafakitale amagalimoto ndi ndege.

Itha kugwiritsidwanso ntchito kupanga mawonekedwe osavuta komanso ovuta.Ubwino wogwiritsa ntchito masitampu azitsulo umaphatikizapo kutsika mtengo, kusinthika kwapangidwe komanso kusinthasintha.

SPM yathandiza makasitomala muzinthu zambiri zopondera zitsulo pazantchito yawo yosinthira, ntchito yathu yaukadaulo yogwira ntchito imatha kupulumutsa ndalama zambiri komanso nthawi.

Jigs ndi zosintha ndi zida zomwe zimagwiritsidwa ntchito pothandizira kupanga magawo ndi zida zosiyanasiyana.

Jig ndi chida chapadera chomwe chimathandiza kutsogolera, kugwira, kapena kuyika chogwirira ntchito m'malo mwa makina osiyanasiyana, monga kubowola, mphero, ndi kupanga.

Zokonza ndi zida zomwe zimamangiriridwa pamakina kapena benchi yogwirira ntchito ndikuthandizira kupeza ndikuteteza zigawozo pamene zikugwiritsidwa ntchito.

Zitha kupangidwa mwachizolowezi kuti zigwirizane ndi ntchito zosiyanasiyana kuti zitsimikizidwe zolondola komanso zogwira mtima.Zojambula zonse ziwiri ndi zowonongeka zimatha kupangidwa ndi zitsulo monga zitsulo kapena aluminiyamu ndipo ndizofunikira pakupanga zigawo zolondola ndi khama lochepa.

SPM imapanga ma jig ndi zokometsera zopangira jekeseni yathu komanso imaperekanso ntchito yopangira makasitomala.

Ngati mukufuna izi, chonde lemberani nthawi iliyonse.

PEZANI MFUNDO YONSE TSOPANO!

-

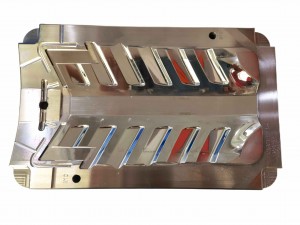

Jekeseni multi cavity nkhungu kwa zipewa za paketi...

-

Pulasitiki tooling banja nkhungu magalimoto mchira lig ...

-

CNC mphero ndi kutembenuza Machining ogulitsa

-

Wopanga jekeseni wa pulasitiki, die castin ...

-

Custom Pulasitiki jekeseni ntchito akamaumba

-

Precision nkhungu pulasitiki jakisoni kwa ogula ...